Monday, December 28, 2009

Nova Pressroom Products Enters Aqueous Coating Licensing Agreement With Lubrizol

Jacksonville, FL, December 21, 2009 – Ronald J. Rose, President of Nova Pressroom Products LLC [Nova] announces an agreement with Lubrizol to license select aqueous coating formulas for the Graphic Arts Industry. “We are very excited to offer printers a seamless transition of their aqueous coatings.” said Mr. Rose. "Lubrizol has excellent technology and a loyal customer base. We have heard from many printers they would prefer not to re-qualify a new coating and risk customer dissatisfaction by switching to another manufacturer’s coating. For coatings being discontinued by Lubrizol, purchasing a Lubrizol-licensed coating from Nova gives them peace of mind."

"We feel the agreement complements our existing Aqueous Coating manufacturing capability. We are mirroring the Lubrizol formulas in every way possible, right down to using the same raw material suppliers used in making the products. Chuck Malspeis, Technical Manager for Nova Coatings is overseeing production and QC to make sure coatings from our Jacksonville, FL facility match Lubrizol’s."

Printers are welcome to call us for pricing, sample qualification or to place orders on performance guarantee.

Nova Pressroom Products is a full line manufacturer of pressroom chemicals including water-based coatings, UV coatings, fountain solutions and press washes.

Contact:

Ronald J. Rose

Nova Pressroom Products LLC

1663 McDuff Ave N

Jacksonville, FL 32254

toll-free: 866.443.5811

fax: 904.292.2665

rrose@novapressroom.com

website: www.novapressroom.com

Monday, November 30, 2009

Pressroom Specialty Kit -- A Sampling of 6 Specialty Products

- SP-579 Plate Clean and Stor

- SP-505 AGE Ashphaltum Gum Plate Etch and Finisher

- SP-515 Plate Cleaner / Scratch Remover

- SP-531 Command Clean All-Purpose Spray Cleaner

- SP-538 Anti-Skin (Non-Aerosol)

- SP-502 14º Be Gum Arabic

Included in each kit are MSDSs for each product along with a product information and instruction sheet. This Specialty Kit is an excellent sample kit for introducing your customers to these fine Nova pressroom accessory products. The suggested list price for the specialty kit is $109.00. All products in the kits are also sold separately.

Want to know more about the Pressroom Specialty Kit? Call Customer Service toll-free: 866.443.5811 or email Ron Rose: rrose@novapressroom.com.

Roller Maintenance Kit -- A Sampling of 6 Specialty Products

- SP-500 Eco-Roller Cream

- SP-526 Super Calcium Remover

- SP-569 Rubber Revitalizer

- SP-596 Chrome Cleaner Desensitizer

- SP-574 Lube-A-Roll

- SP-520 Dampening Systems Cleaner

Nova's SP-1000K Roller Maintenance Kit comes packaged in a handy Nova logo canvas tote/cooler. You’ll want this kit to keep your rollers in top condition – condition, clean, lube, and desensitize.

Included in each kit are MSDSs for each product along with a product information and instruction sheet. This Specialty Kit is an excellent sample kit for introducing your customers to these fine Nova pressroom accessory products. The suggested list price for the specialty kit is $109.00. All products in the kits are also sold separately.

Want to know more about the Roller Maintenance Kit? Call Customer Service toll-free: 866.443.5811 or email Ron Rose: rrose@novapressroom.com.

Thursday, May 21, 2009

Calcium Remover, Industrial Strength Cleaner and Sheetfed Aqueous Coating

SP-531 Command-Clean is a ready to use industrial strength spray cleaner to remove ink, grease and grime for use on most hard surfaces such as vinyl, rubber, plastic, metal, ceramic and painted surfaces. It is ideal for use on press side frames, walls, bindery equipment, plate cylinders and general cleaning in the pressroom, prepress, bathrooms and kitchens. Supplied in quart bottles with trigger sprayer.

NovaCoat AQ-633 is an ultra-fast drying aqueous coating designed for sheetfed coaters. NovaCoat AQ-633 has excellent flexibility, adhesion to non-porous substrates, dry speed and non-blocking character. NovaCoat AQ-633 has low odor and low VOC and adequate gloss, is slippery and is not recommended to be recoated.

Printers who are battling blocking or rub/scuff issues, have short delivery/insufficient drying capacity, or coat over non-porous substrates, including synthetic papers or plastics should try NovaCoat AQ-633. Please call customer service for MSDS, TDS or samples. For technical questions, call Chuck Malspeis at 904-292-2554.

Product data sheets and MSDSs are available on our web site. To contact Customer Service or a Nova Technical Staff member call 904-292-2554 or visit the website at http://www.novapressroom.com/.

Monday, April 27, 2009

Nova Announces Corporate Headquarters Move in Jacksonville, FL

“We believe bringing the business operation to the same campus with manufacturing and research will allow for more efficiencies as we continue to grow,” stated Ron Rose, President of NOVA Pressroom Products. “We continue to be honored by the enthusiastic support of our customers as we work to achieve our goal of becoming a major supplier of safe, cost-effective and environmentally-compliant pressroom products.”

The 23,500 square foot plant opened in January 2008 is the site for manufacturing NOVA fountain solutions, water-based coatings and UV coatings to support sales efforts domestically and internationally. The facility also contains research laboratories for NOVA’s main product lines. The company markets its products through a network of dealers in the United States, Canada, Latin America and Asia.

Founded in February 2007, NOVA Pressroom Products has dedicated its over 75 years of industry-related technical experts to formulating environmentally-compliant products that address problem-solving and regulatory requirement needs of printers worldwide.

To contact Customer Service or a NOVA Technical Staff member call 904-292-2554. Product information along with product data sheets, MSDSs and technical tips can be viewed on our easy-to-use NOVA website found at http://www.novapressroom.com/.

Additional information along with new product updates can be found on our blog at http://novapressroom.blogspot.com/.

# # #

NEW ADDRESS

1663 North McDuff Avenue

Jacksonville FL 32254

Tel: 1-866-443-5811

Fax: 1-904-292-2665

For additional information contact Ronald J. Rose toll-free at 1-866-443-5811 or via email to rrose@novapressroom.com.

Originally published: April 21, 2009.

Monday, March 16, 2009

NovaCoat Strike-Through UV Coating System

Nova Pressroom Products is pleased to announce an industry first from Nova! It's the NovaCoat Strike-Through System: Single-Pass High Contrast Dull Varnish + UV Gloss Coating for Sheetfed Presses. The two innovative products that comprise this strike-through system are:

- Nova SP-595 Dull Varnish

- NovaCoat UV-705 Gloss UV Coating

This system is a combination of conventional dull varnish + UV gloss topcoat for sheetfed presses. This system is specially formulated to run in-line and to achieve maximum gloss contrast. When dry, both glossy and dull areas have outstanding rub resistance. Gloss contrasts of 70 points have been achieved! Because the dull varnish is applied via standard lithography, the most exacting and intricate designs can be achieved. The conventional dull varnish will not damage UV rollers.

- Works with UV or Conventional Ink Units – no need to replace rollers!

- Excellent adhesion without aqueous primer.

- Outstanding gloss contrast and rub resistance.

- Low odor.

- NovaCoat UV-705 can be used as conventional high gloss UV coating.

N-444 Wash, N-480UV Wash, and SP-579 Plate Clean & Stor

N-480UV Wash – A 10% VOC, Southern California Rule 1171 compliant UV Wash. Compatible with all roller materials, cleans both hybrid & UV inks.

SP-579 Plate Clean & Stor – A multi-purpose emulsion plate cleaner and preserver. It is designed to be compatible with all types of positive and negative plates. SP-579 contains effective ink solvents, desensitizers, and non-blinding gum plate preservatives to be the one all-purpose plate cleaner preservative to meet your needs.

Additional information, product sheets, MSDS’s and technical tips can be viewed on our easy-to-use NOVA website http://www.novapressroom.com/.

To contact Customer Service or a NOVA Technical Staff member call 904-292-2554.

Solvent Prices - Important Update for Our Customers

Last year, the oil price run-up caused significant disruption in the Blanket & Roller Wash market. Prices were increased to end users by an average of 42%. Nova committed to our customers that prices would be reduced as the cost of solvents came down. In the past few months, Nova has reduced its distributor prices three times. Nova was founded to provide high quality pressroom chemicals with great value. Our products still meet that test. If your customers have questions about solvent pricing or are looking for a lower cost alternative, give us a call. We’re here to help.

--Ron Rose, President

Friday, March 13, 2009

Nova Expands into Latin American Market

NOVA Pressroom Products LLC announces the appointment of Mr. Jose Colon, Guaynabo, Puerto Rico, as Senior Technical Sales Representative. Mr. Colon joins this technology-based manufacturer of a full line of pressroom products as it expands into the Latin American market.

NOVA Pressroom Products LLC announces the appointment of Mr. Jose Colon, Guaynabo, Puerto Rico, as Senior Technical Sales Representative. Mr. Colon joins this technology-based manufacturer of a full line of pressroom products as it expands into the Latin American market.Mr. Colon brings over 22 years of technical knowledge and experience in graphic arts consumable products including film, chemicals, plates, coatings, inks and press products.

He is widely recognized throughout Central America, the Caribbean and South America as the “go-to guy” to solve a wide range of technical issues.

Ronald J. Rose, President of NOVA stated, “Adding Jose Colon to the NOVA Technical Team has empowered our plans to move into the Latin American marketplace. Jose brings a unique sales and technical background covering all areas of offset printing. He is recognized by dealers and printers in the area as an invaluable resource.”

Founded in February 2007, NOVA Pressroom Products has over 75 years of experience formulating high performance environmentally-compliant products that address problem-solving and regulatory requirement needs of printers throughout North America and Asia.

The corporate office and call center is located in Jacksonville, Florida with a 23,500 square foot manufacturing and research facility in North Jacksonville.

Additional information, product sheets, MSDS’s and technical tips can be viewed on our easy-to-use NOVA website http://www.novapressroom.com/. More new product updates and more information, be sure to visit the NOVA blog http://novapressroom.blogspot.com/. To contact Customer Service or a NOVA Technical Staff member call 904-292-2554.

# # #

For additional information contact Ronald J. Rose toll-free at 866-443-5811 or via email to rrose@novapressroom.com or Jose Colon, Senior Technical Sales Representative at 787-998-0460 or 305-799-6460. SKYPE: jose.colon7 or via email to jcolon@novapressroom.com.

Originally published: March 10, 2009.

Monday, March 9, 2009

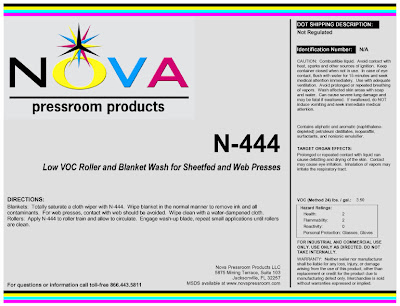

Nova Announces N-444 -- Low VOC Blanket and Roller Wash

Nova announces N-444, a 50% (3.5 lbs./gal. VOC) water emulsion blanket and roller wash. This is a low VOC wash for sheetfed and web presses.

A number of you have accounts that were using the Day/Varn Ecolo-Clean 35 which has recently been discontinued. The Nova N-444 is a similar emulsion wash product that should easily substitute for this product. N-444 is available now.

N-444 is a stabilized water / solvent emulsion cleaner for sheetfed and cold set web presses. It has low VOC with 3.50 lbs./gal. VOC and has a high flash point of 145°F. It contains no mineral or vegetable oil and therefore will dry and leave no oily residue. N-444 provides the benefit of a water-miscible wash while having built in low VOC to meet tough permitting requirements.The product data sheet and MSDS are available on our web site. Contact Ray Brady if you have questions, need samples or want pricing. To contact Customer Service or a Nova Technical Staff member call 904-292-2554 or visit the website at http://www.novapressroom.com/.

Thursday, February 19, 2009

CPSIA -- Consumer Product Safety Improvement Act

To Whom It May Concern,

This letter is written to address lead and phthalate compounds content in Nova Pressroom Products as it pertains to the Consumer Product Safety Improvement Act (CPSIA).

Nova has performed a review of the MSDSs and specification sheets for all raw materials used to manufacture Nova products. All materials are compliant with the CPSIA guidelines with regard to the levels of lead and phthalate compounds. The threshold level of compliance for lead in printed materials that fall under the CPSIA regulation is currently 600 ppm, effective February 10, 2009, and subsequently 300 ppm, effective August 14, 2009. There are no Nova products that have a lead content greater than 0.1 ppm; therefore, the use of Nova products during the printing process would not contribute to the failure of a printed material under the proposed CPSIA testing procedures.

In addition, there are no detectable levels of phthalate compounds in any Nova product.

On January 30, 2009, The Consumer Product Safety Commission (CPSC) granted a one-year stay of enforcement for testing and certification of children’s products and toys subject to the CPSIA. The stay postpones the requirement for printers to test and certify their products against the new lead and phthalate standards. The new implementation deadline is February 10, 2010.

For more information on the CPSIA, I have included the links below that may be helpful.http://cpsc.gov/cpscpub/prerel/prhtml09/09115.html

http://www.pimn.org/about/CPSIA.htm

http://www.cpsc.gov/cpsia.pdf

Ray Brady

VP Technical Services

Nova Pressroom Products

Download a copy of Nova's CPSIA Statement.

Monday, January 26, 2009

Innovative products for the Graphic Arts Industry -- You know us!

Look for us at Graphics of the Americas -- Booth 242 in Hall C.

Look for us at Graphics of the Americas -- Booth 242 in Hall C. Nova Pressroom Products -- You know us!

Innovative products for the Graphic Arts Industry

Alcohol Substitutes, Aqueous Coatings, Blanket & Roller Washes, Fountain Solutions, Silicone Emulsions, Specialty Products, and UV Coatings.

¡Usted nos conoce!

Productos innovadores para la industria de Artes Gráfica

Sustitutos del Alcohol, Recubrimientos Base Aqua, Lavadores de Mantillas y Rodillos, Soluciones de Fuente, Emulsiones de Silicon, Productos Especiales, and Recubrimientos UV.

Website: www.novapressroom.com/

Blog: novapressroom.blogspot.com

Monday, January 12, 2009

Visit us at Graphics of the Americas 2009

Don't wait in line at the show! You can register early to get your free expo pass by downloading and completing one of these forms: English or Spanish.

We hope that you will drop by our booth.